When we operate a factory to cut steel pipes or other metals or woods, we need to source the best-matching and long time durable-working alloy saw blades as production tools,but where to import the good quality at a reasonable low prices? My suggestion is to buy from China, to buy from Halifegroup.com…Alloy saw blades made in China are often highly regarded for cutting steel pipes due to several factors, including advanced manufacturing processes, quality materials, and competitive pricing. Here are some key reasons why these blades perform well:

1. High-Quality Materials:

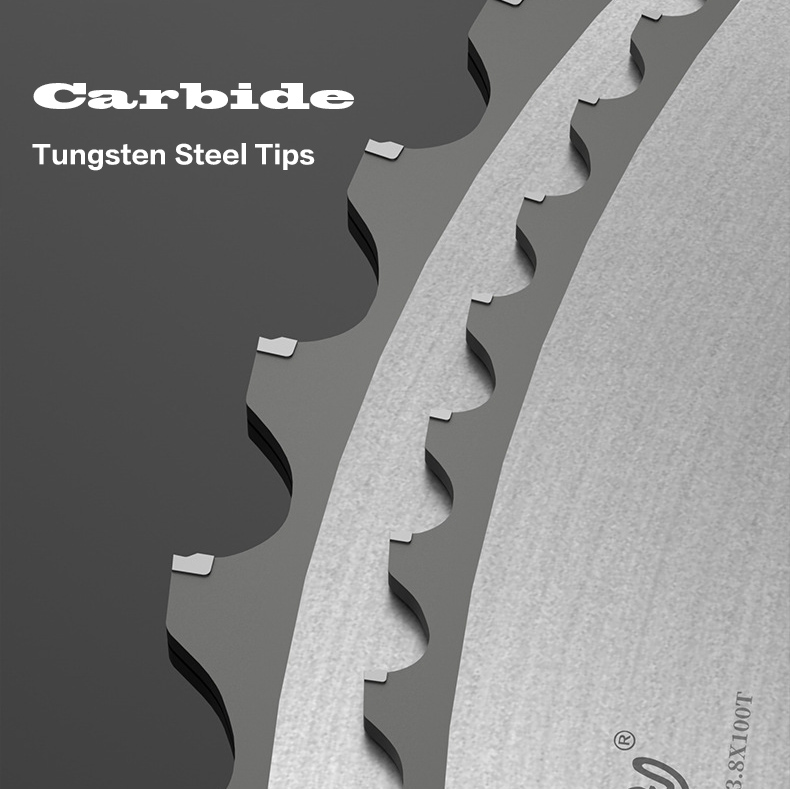

- Tungsten Carbide Tips: Many high-quality Chinese alloy saw blades use tungsten carbide tips, which are extremely hard and durable. Tungsten carbide is known for its ability to withstand high temperatures and maintain sharpness, making it ideal for cutting through tough materials like steel.

- Steel Body: The body of the blade is often made from high-grade steel, such as high-speed steel (HSS) or tool steel, which provides the necessary strength and flexibility to handle the stress of cutting.

2. Advanced Manufacturing Techniques:

- Precision Grinding: Chinese manufacturers often use advanced grinding techniques to ensure that the teeth of the saw blades are precisely shaped and aligned. This precision leads to cleaner cuts and longer blade life.

- Heat Treatment: Proper heat treatment processes, such as tempering and quenching, are used to enhance the hardness and durability of the blade. This helps the blade resist wear and maintain its edge over time.

3. Innovative Designs:

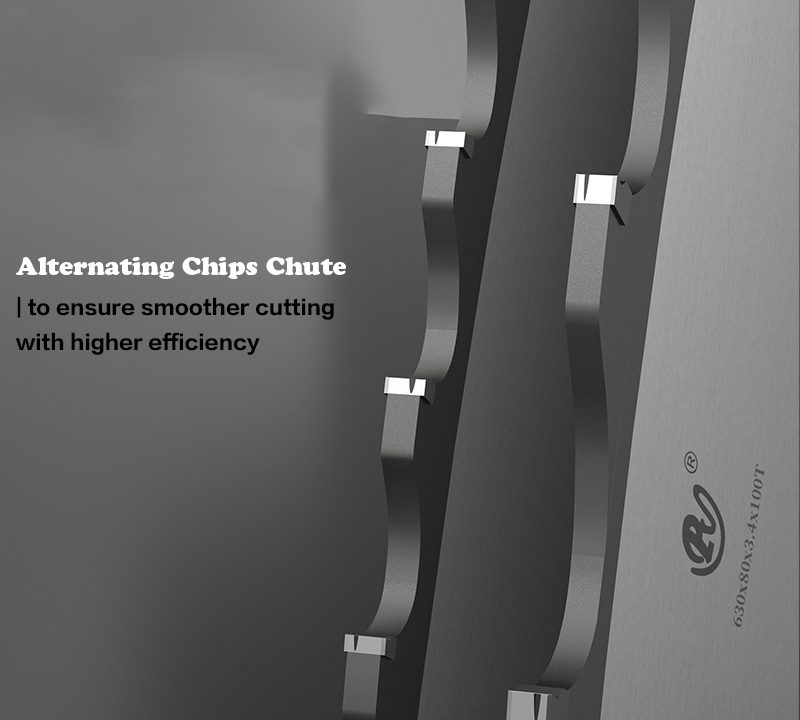

- Tooth Geometry: The design of the teeth, including their shape, angle, and spacing, is optimized for specific applications. For cutting steel pipes, the teeth are designed to efficiently remove material and dissipate heat, reducing the risk of damage to the blade and the workpiece.

- Anti-Vibration Features: Some blades incorporate anti-vibration features, such as laser-cut expansion slots or dampening systems, which help to reduce chatter and improve the quality of the cut.

4. Cost-Effectiveness:

- Economies of Scale: Chinese manufacturers benefit from economies of scale, allowing them to produce high volumes of saw blades at a lower cost. This cost advantage is often passed on to consumers, making high-quality blades more affordable.

- Competitive Pricing: Despite the high quality, many Chinese-made blades are priced competitively, offering good value for money.

5. Quality Control:

- Stringent Standards: Reputable Chinese manufacturers adhere to strict quality control standards, ensuring that each blade meets the required specifications. This includes rigorous testing for hardness, balance, and performance.

- Certifications: Many Chinese factories have obtained international certifications, such as ISO 9001, which indicates that they meet global standards for quality management.

6. Customization and Variety:

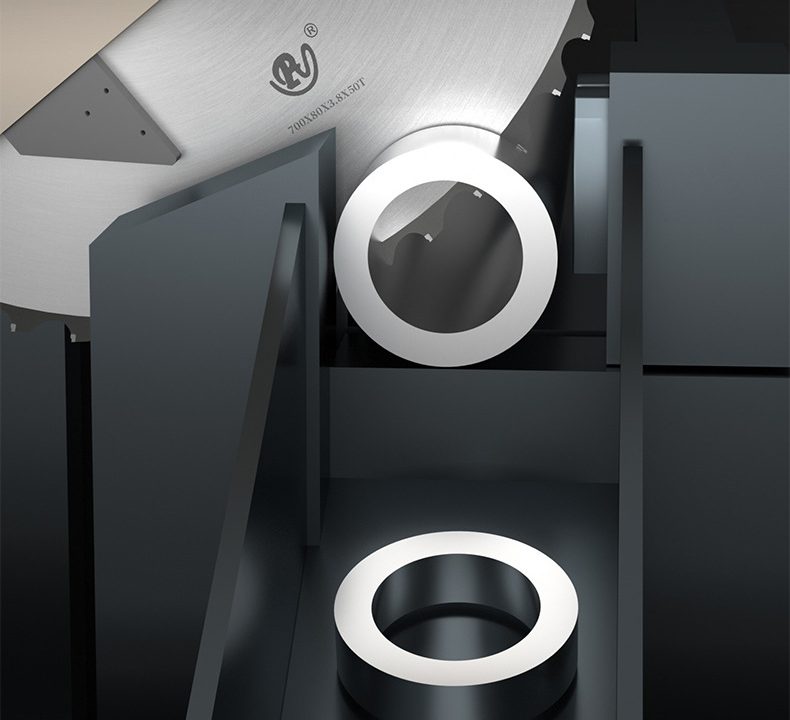

- Wide Range of Options: Chinese manufacturers offer a wide range of saw blades with different sizes, tooth configurations, and coatings, allowing users to choose the best blade for their specific application.

- Custom Solutions: Some manufacturers can provide custom-made blades tailored to the needs of specific industries or applications, ensuring optimal performance.

7. Technological Investment:

- R&D Investment: Many Chinese companies invest heavily in research and development, constantly improving their products and introducing new technologies. This investment in innovation helps to keep their products at the forefront of the industry

8. Global Supply Chain:

- Access to Global Markets: Chinese manufacturers have access to a global supply chain, allowing them to source the best raw materials and components from around the world. This ensures that the final product is of high quality and reliable.

By combining these factors, Chinese manufacturers are able to produce alloy saw blades that are effective, durable, and cost-effective for cutting steel pipes and other tough materials. However, it’s important to choose reputable manufacturers and brands to ensure that you get a high-quality product.