It is very important to forecast the development trends when you plan to run into a new industry, and the metal-pipes cutting business always to develop together with local economic’s growth…do you think will it be a good business to input in Southeast Asia area?The metal-pipe cutting industry in Southeast Asia is poised for significant development driven by several factors including economic growth, industrialization, infrastructure projects, and technological advancements. Here’s a detailed look at the potential directions and trends shaping this sector:

1. Economic Growth and Industrial Expansion

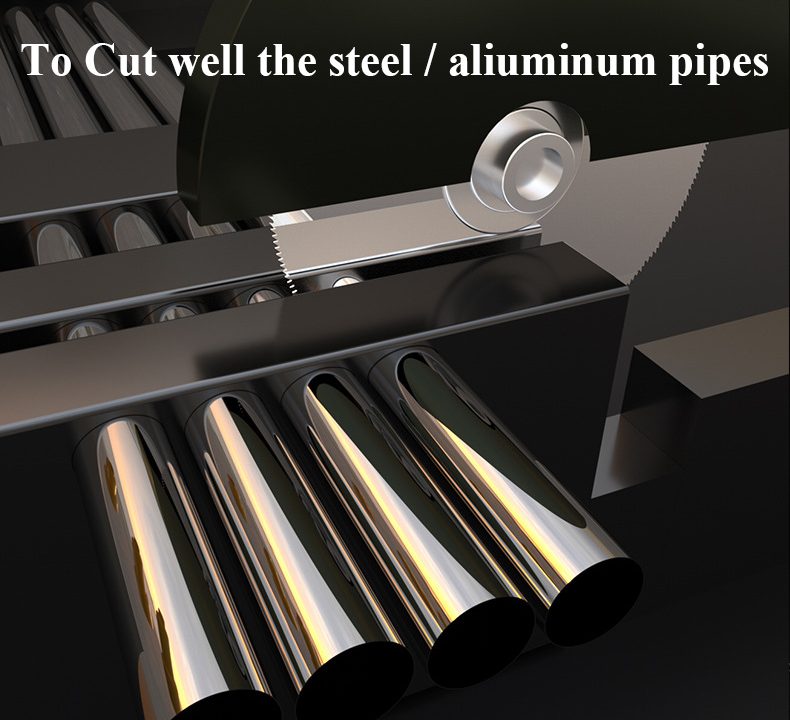

- Increasing Demand: Rapid economic growth across Southeast Asian countries such as Vietnam, Thailand, Malaysia, Indonesia, and the Philippines is driving demand for metal pipes in various industries like construction, oil & gas, automotive, and manufacturing.

- Industrial Zones: The establishment of new industrial zones and economic corridors will require extensive piping systems, further boosting the market.

2. Infrastructure Development Projects

- Government Initiatives: Governments in these regions are investing heavily in infrastructure development, including transportation networks, utilities, and urban development projects, all of which rely on metal pipes.

- Urbanization: Growing urban populations necessitate improvements in water supply, sewage systems, and other municipal services that depend on reliable pipe solutions.

3. Technological Advancements

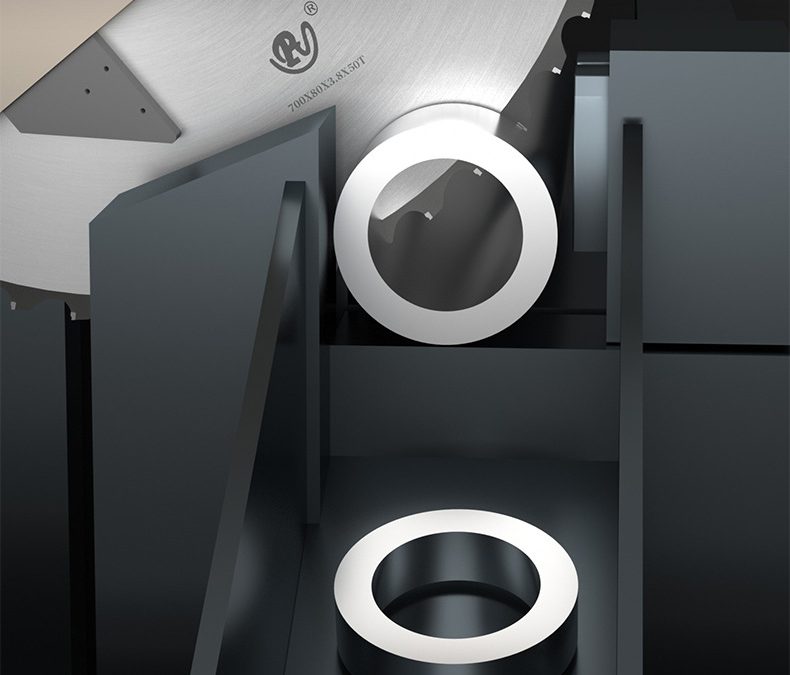

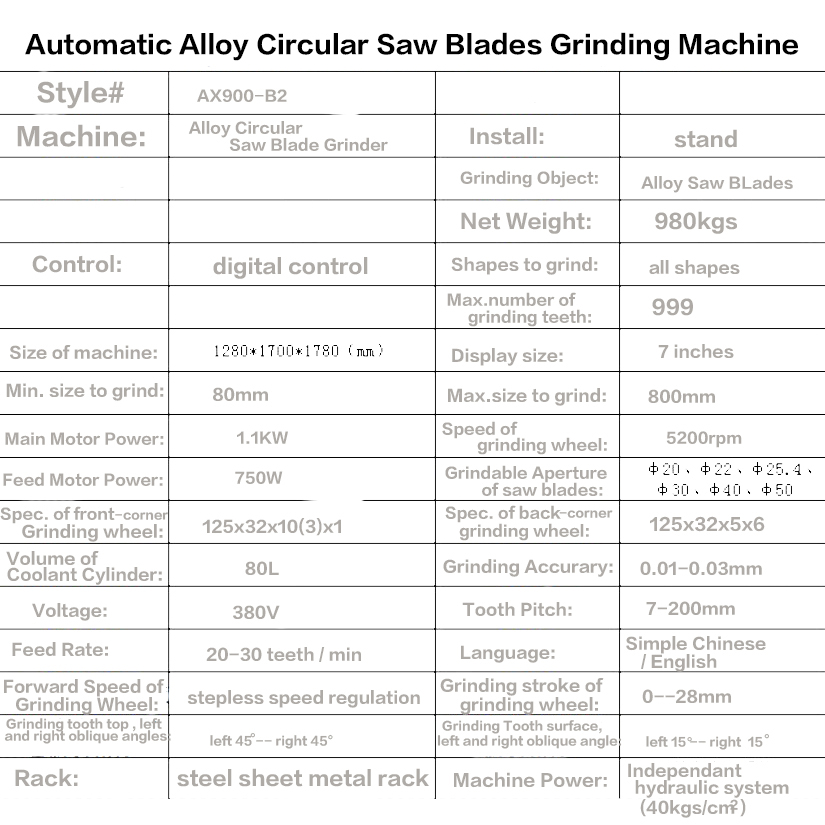

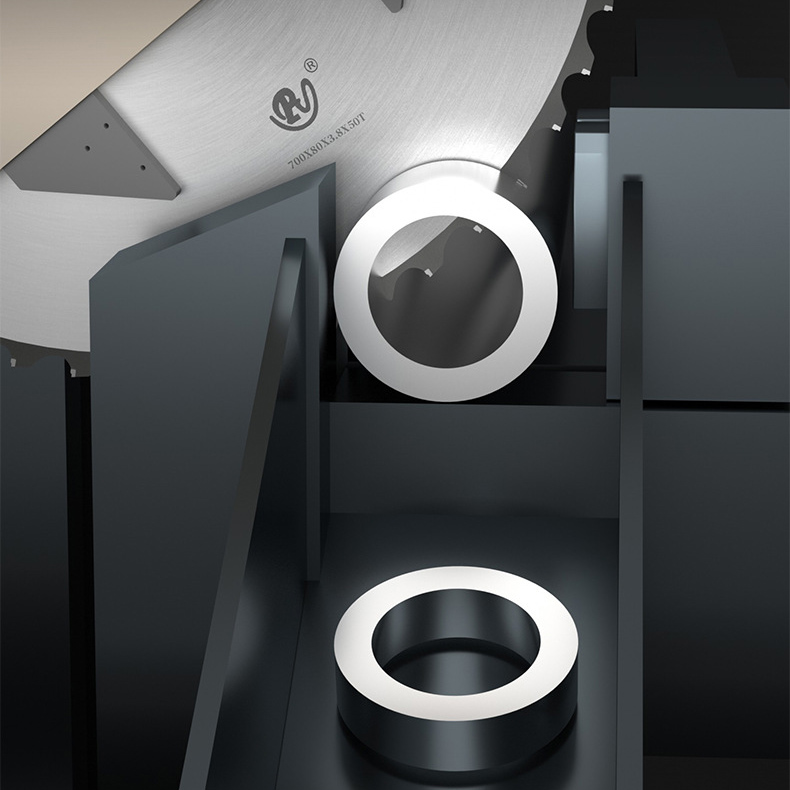

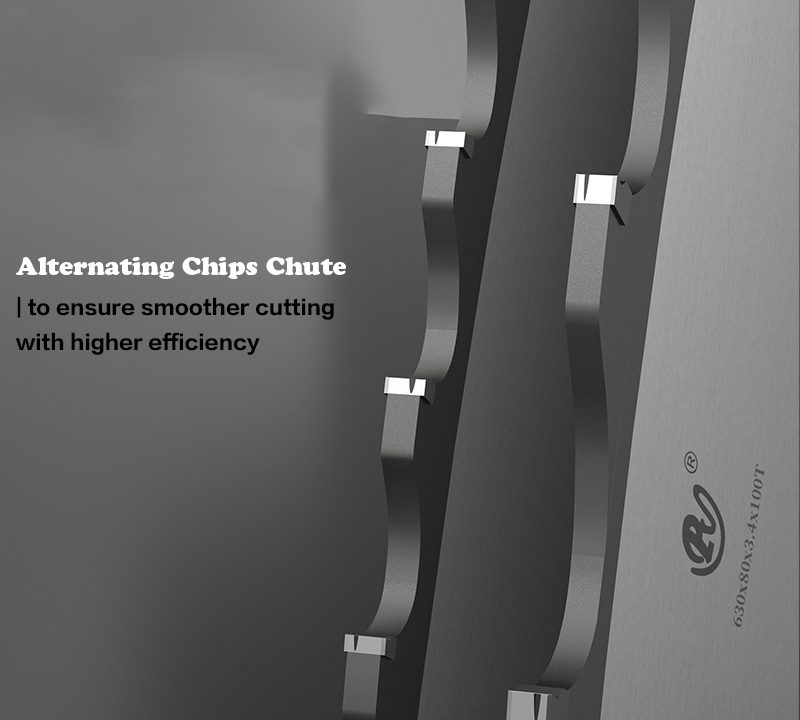

- Automation and Precision Cutting: Adoption of advanced technologies like laser cutting, plasma cutting, and CNC machines is improving efficiency and precision while reducing material waste.

- Innovative Materials: Introduction of corrosion-resistant alloys and high-strength materials enhances durability and extends the life of metal pipes, making them more attractive for long-term projects.

4. Sustainability and Environmental Considerations

- Green Building Standards: Increasing awareness about sustainability is leading to stricter regulations regarding material selection and disposal practices. This encourages manufacturers to produce eco-friendly products.

- Recycling Initiatives: Promoting recycling programs for metal scraps can reduce environmental impact and lower production costs through resource recovery.

5. Supply Chain Optimization

- Local Manufacturing Capacity: Strengthening local manufacturing capabilities reduces dependency on imports and ensures timely delivery of quality products.

- Logistics and Distribution Networks: Enhancing logistics infrastructure improves distribution efficiency, allowing quicker response times to meet fluctuating market demands.

6. Regulatory Environment

- Trade Agreements: Bilateral and multilateral trade agreements facilitate smoother cross-border commerce, benefiting both suppliers and buyers within the region.

- Safety and Quality Standards: Harmonizing safety and quality standards with international norms increases consumer confidence and opens up export opportunities.

7. Market Dynamics

- Competitive Landscape: Intense competition among regional players promotes innovation and cost-effectiveness. Smaller enterprises may collaborate or form strategic alliances to compete effectively against larger corporations.

- Customer Preferences: Understanding customer needs and preferences helps tailor offerings to specific applications, thereby enhancing customer satisfaction and loyalty.

Case Studies and Trends

Vietnam

- Economic Hub: Vietnam has emerged as an economic hub with strong growth rates, attracting foreign direct investment (FDI) into its manufacturing sector. The country’s push towards industrialization and modernization creates substantial demand for metal pipes used in factories, power plants, and residential buildings.

Thailand

- Agriculture to Industry Shift: Transition from agriculture-based economy to industry-oriented one requires robust pipeline infrastructure for irrigation, drainage, and energy transmission systems.

Indonesia

- Archipelagic Challenges: Given its geography, Indonesia faces unique challenges in connecting remote islands. Investment in maritime infrastructure, including ports and pipelines, becomes crucial for national integration and economic cohesion.

Philippines

- Disaster Resilience: Frequent natural disasters highlight the need for resilient and durable piping systems capable of withstanding extreme weather conditions.

Conclusion

The metal-pipe cutting industry in Southeast Asia is expected to witness robust growth fueled by ongoing economic activities, infrastructural developments, and adoption of innovative technologies. Companies operating in this space should focus on leveraging these opportunities while addressing environmental concerns and regulatory requirements to achieve sustainable success. By staying attuned to market dynamics and evolving customer preferences, stakeholders can position themselves favorably in this dynamic and promising sector.