When we wanna open a new factory for cutting metal pipes, it is not just import the advanced metal-pipes cutting machines, alloy saw blades grinding system and excellent alloy saw blades…it is still many other things to take care and operate well, then you can get a chance to gain business from it…Operating a new metal-pipes cutting factory efficiently and effectively involves several key steps that cover planning, safety, production management, quality control, and continuous improvement. Here’s a comprehensive guide to help you manage your factory successfully:

1. Planning and Setup

- Facility Layout: Design an efficient layout that minimizes material handling distances and maximizes workflow. Consider the flow of raw materials into the facility, through processing areas, and out as finished products.

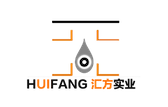

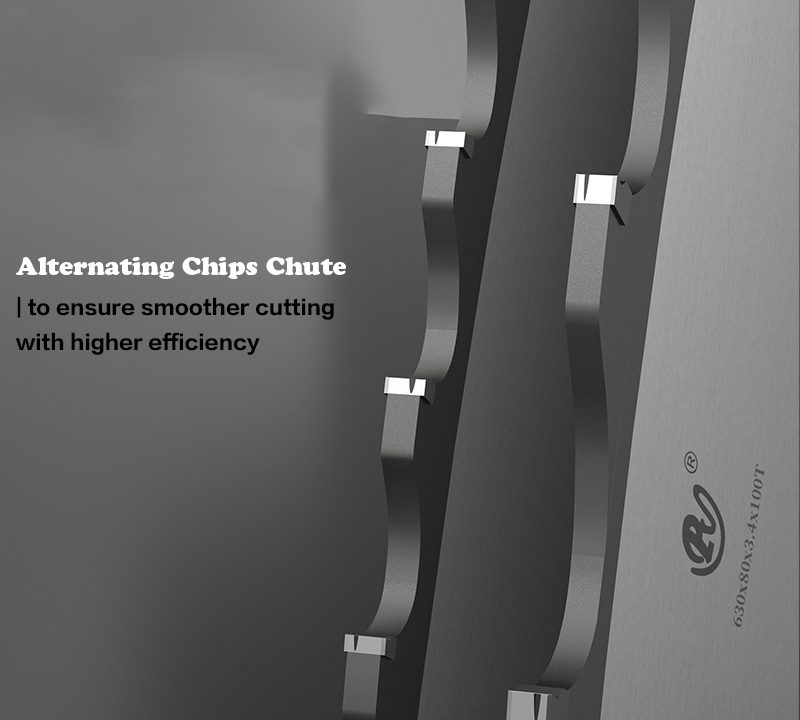

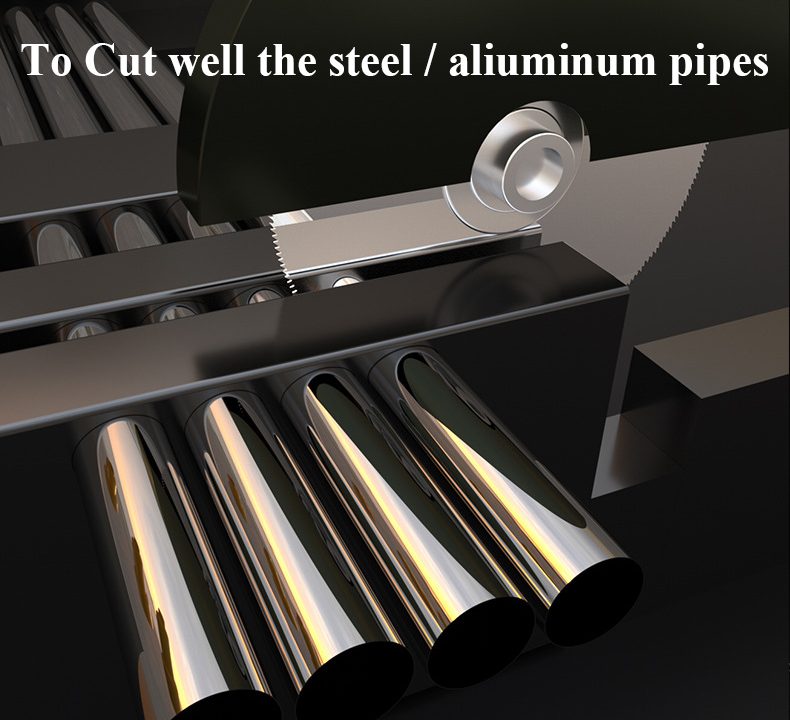

- Equipment Selection: Choose high-quality machinery suitable for the types of pipes you plan to cut. Ensure equipment is properly installed, calibrated, and maintained.

- Technology Integration: Implement advanced manufacturing technologies like CNC machines, robotic systems, and automation where appropriate to improve efficiency and reduce human error.

2. Safety Measures

- Safety Protocols: Establish strict safety protocols including personal protective equipment (PPE) requirements, machine guarding, and emergency procedures.

- Training Programs: Provide comprehensive training for all employees on safety practices, equipment operation, and maintenance procedures.

- Regular Inspections: Conduct regular inspections of machinery and work environments to identify potential hazards and ensure compliance with regulations.

3. Production Management

- Scheduling: Develop a detailed production schedule that aligns with customer orders and inventory levels. Use software tools for better scheduling and tracking.

- Lean Manufacturing: Adopt lean principles to eliminate waste in processes, such as overproduction, waiting times, unnecessary transport, etc.

- Inventory Control: Maintain optimal stock levels of raw materials and finished goods using just-in-time (JIT) inventory methods or other effective strategies.

4. Quality Assurance

- Inspection Standards: Define clear inspection standards and checkpoints throughout the production process to catch defects early.

- Certification Compliance: Ensure adherence to relevant industry standards and certifications (e.g., ISO, API).

- Continuous Improvement: Regularly review and refine quality control processes based on feedback from customers and internal audits.

5. Environmental Responsibility

- Waste Reduction: Implement measures to minimize waste generation and recycle scrap materials whenever possible.

- Energy Efficiency: Optimize energy consumption by upgrading to energy-efficient equipment and implementing best practices for power usage.

- Regulatory Compliance: Stay informed about environmental laws and regulations affecting your operations and ensure full compliance.

6. Customer Relationship Management

- Communication Channels: Establish reliable communication channels with customers for order tracking, updates, and resolving issues promptly.

- Feedback Mechanisms: Encourage customer feedback to understand their needs and expectations better, which can drive product improvements and service enhancements.

7. Employee Engagement

- Motivation and Retention: Foster a positive workplace culture that values employee contributions and offers opportunities for professional development.

- Team Building: Organize team-building activities to enhance collaboration among staff members across different departments.

8. Financial Management

- Cost Control: Monitor costs closely related to procurement, labor, overhead, and capital expenditures to maintain profitability.

- Budgeting and Forecasting: Prepare accurate budgets and forecasts to guide financial decision-making and resource allocation.

9. Technology and Innovation

- R&D Investment: Allocate resources for research and development to explore new cutting techniques, materials, and market opportunities.

- Automation and AI: Explore the integration of artificial intelligence and machine learning to optimize operations further and predict maintenance needs.

By focusing on these areas, you can establish a well-operated metal-pipes cutting factory that not only meets current demands but also positions itself for long-term success in a competitive market. Always be prepared to adapt to changes in technology, market conditions, and customer preferences.