Saw blade grinding machines are essential tools in industries where cutting precision and durability of cutting tools are critical. These industries often involve the processing of materials that require sharp, durable, and maintainable cutting edges. Installing a saw blade grinding machine involves several steps to ensure that the equipment operates safely and efficiently. Here’s a general guide on how to install such a machine:

Preparation

- Read the Manual: Before starting any installation process, thoroughly read the manufacturer’s manual for specific instructions and safety guidelines.

- Site Preparation: Choose a location with enough space around the machine for maintenance and operation. Ensure the area is clean and free from debris.

- Electrical Requirements: Verify the electrical requirements of the machine and make sure your facility can meet these needs. You may need to consult an electrician for proper wiring and grounding.

Installation Steps

- Unpack the Machine: Carefully unpack the machine and inspect it for any damage during shipping. Report any issues to the supplier immediately.

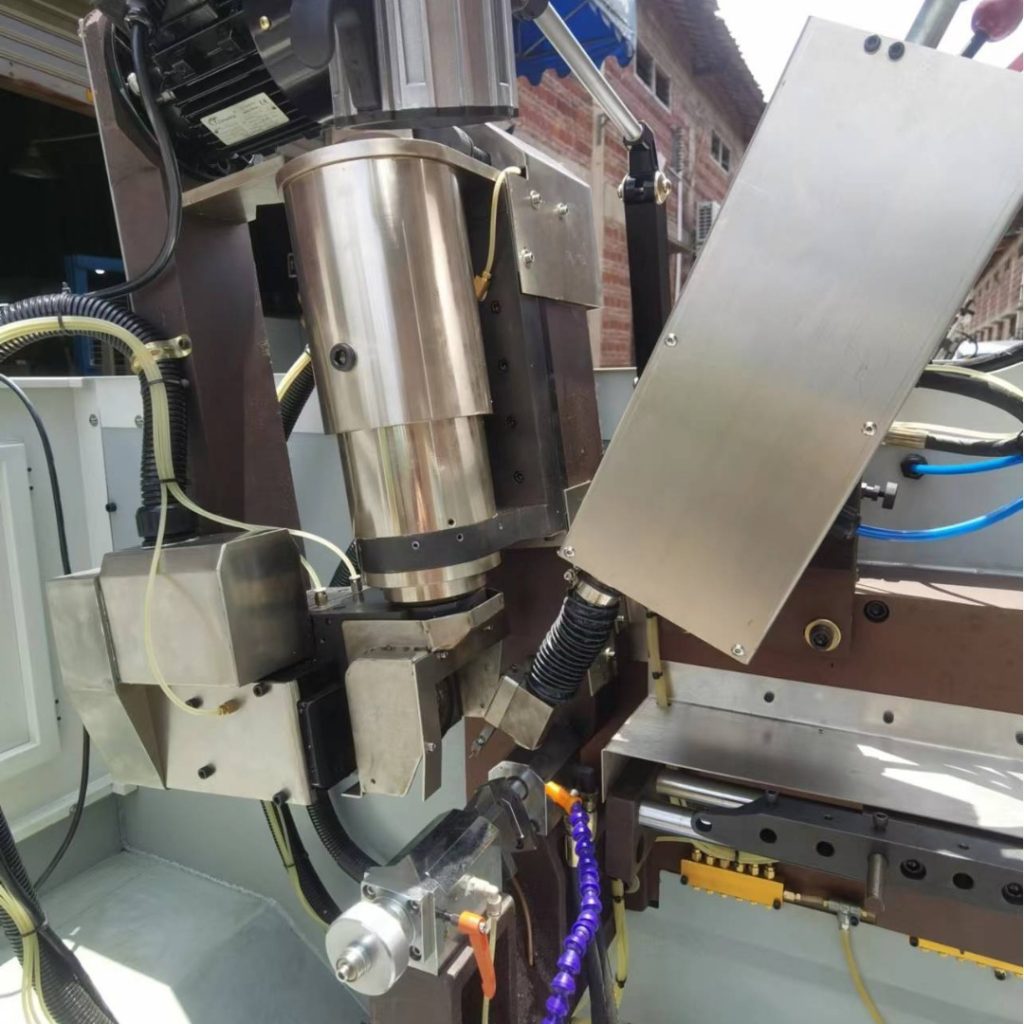

- Position the Machine: Move the machine into its designated location using appropriate lifting or moving equipment. The floor should be level and stable.

- Leveling: Use a spirit level to check that the machine is perfectly horizontal. Adjust the leveling feet as necessary to achieve this.

- Connect Electrical Supply: Connect the machine to the power supply according to the manufacturer’s specifications. Ensure that the power supply meets the voltage and amperage requirements of the machine.

- Install Dust Collection System (if applicable): If the machine requires a dust collection system, install it according to the manufacturer’s instructions. This typically involves connecting ductwork and ensuring that the system is properly sealed.

- Install Coolant System (if applicable): If the machine uses a coolant, set up the coolant delivery system. This might involve connecting hoses and filling the reservoir with the recommended coolant.

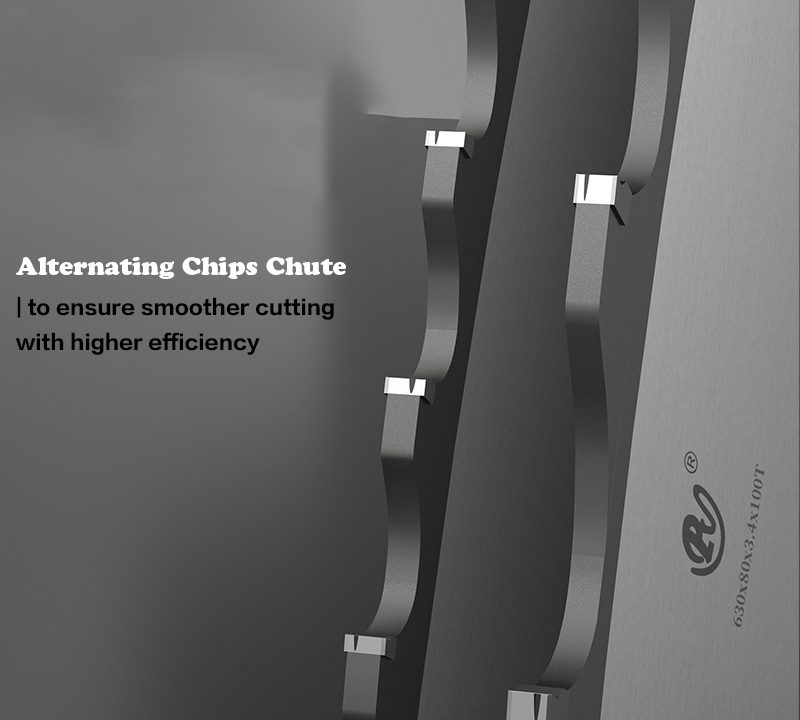

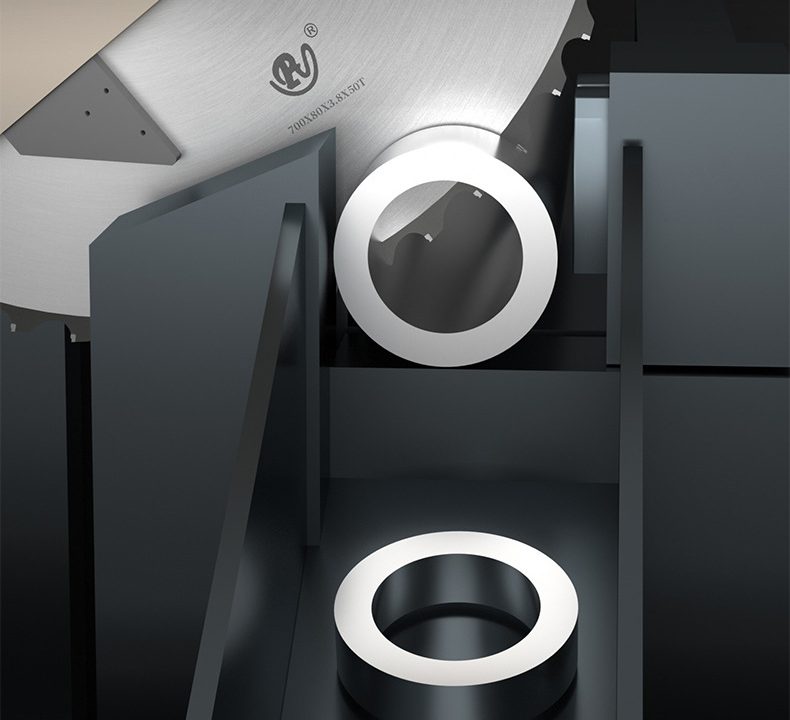

- Mount Grinding Wheels: Install the grinding wheels onto the machine following the manufacturer’s guidelines. Make sure they are securely fastened and balanced properly.

- Safety Checks: Before operating the machine, perform a thorough safety check. Ensure all guards are in place, emergency stops are functional, and safety interlocks are working correctly.

- Test Run: After completing the installation, run the machine through a test cycle without any load. Observe for any unusual noises or vibrations and make adjustments as needed.

- Training: Train operators on the safe use and maintenance of the machine. Provide them with the manual and any additional training materials.

Post-Installation

Post-Installation

- Documentation: Keep a record of the installation process, including any adjustments made and the final settings.

- Maintenance Schedule: Establish a regular maintenance schedule to keep the machine running smoothly. Follow the manufacturer’s recommendations for lubrication, cleaning, and part replacement.

Safety Precautions

- Always wear appropriate personal protective equipment (PPE) when handling machinery.

- Ensure the area around the machine is clear of obstructions and hazards.

- Follow all local regulations and standards regarding industrial machinery installation.

Each saw blade grinding machine may have unique installation requirements, so it’s crucial to follow the specific instructions provided by the manufacturer. If you’re unsure about any step in the process, consult a professional installer or contact the manufacturer for assistance.